Liquid penetrant testing

What is a uniqueness of the penetrant testing?

Penetrant testing is based on special liquids ability to penetrate into the defects. The resulting contrast image allows to evaluate the state of material. Using this method, it is possible to detect surface defects of products made from non-metals and alloys, which are inaccessible to the magnetic method.

Penetrant testing process

PT method is especially effective for the detection of flaws with the following parameters:

- width of 1 micron;

- depth of more than 10 microns;

- length of 0.1 mm.

Testing represents a sequence of several operations:

1. Cleaning and deoiling of the testing surface.

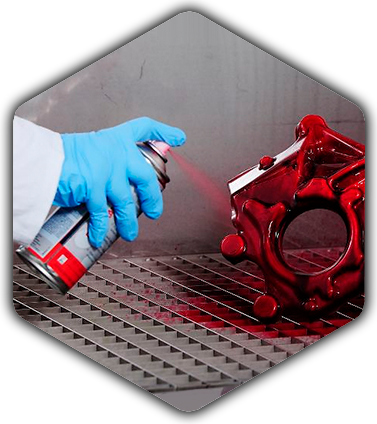

2. Indicator laying, filling of the defective area. The accelerated penetration of liquids is practiced by increasing and decreasing of the pressure, influence of ultrasonic and acoustic waves on the material, indicator heating, the use of static load on the subject, etc.

3. Freeing of liquid excess. The composition is blown away or wiped in such way that it remains only in defects.

4. Laying of developing agent. Brushes, brooms and sprays are used to do it. The developing agent is produced in the form of a powder or in the form of a phosphor bath which glow when exposed to ultraviolet light.

5. Drying of developing agent, absorption of the indicator liquid, tinting the defective areas.

The liquid appears at edges of the defects and evaporates adding the dye in the indicator liquid and heating. Solidified developing agent allows to evaluate amount and position of the defects. Enlarging lens and photo sensors are used to detect them.

LLP «ARDCON» offers services of welding and metal testing laboratory. The laboratory is certified to the following control methods: radiographic testing, ultrasonic flaw detection, ultrasonic thickness measurement, metal hardness measurement, liquid penetrant testing, magnetic particle inspection and other NDT methods. For consultation, a potential customer can contact with our technical specialists and discuss the questions.

Tel. +7 (7212) 996606,

Tel. +7 (708) 4360630

M02F3P7, Republic of Kazakhstan,

Karaganda region, Karaganda,

st.Navigational 7, housing 2

E-Mail: info@ardcon.kz