УЛЬТРАДЫБЫСТЫҚ ҚАЛЫҢДЫҚТЫ ӨЛШЕУ

Ультрадыбыстық қалыңдықты өлшеу не үшін қажет?

ББ технологияларының бірі бола отырып, ультрадыбыстық қалыңдықты өлшеу металдың техникалық жағдайын бағалауға мүмкіндік береді. ARDCON компаниясында функционалдығы мен қарапайым интерфейсі бар түрлі портативті өлшеуіштер бар. Оларды қолданудың арқасында материалдың қалдық қалыңдығы мен оның коррозиялық зақымдану дәрежесі туралы толық ақпарат ала аласыз. Бұл диагностика түрі объектінің зақымдалуын және оны пайдаланудан шығаруды болдырмайды.

Әдістің физикалық негіздері және басты артықшылықтары

Бұл әдісті іске асыру металдың ультрадыбыстық тербелістерді қайтару қабілетіне байланысты мүмкін болды. Арнайы құрылғы осы тербелістерді тіркейді және олардың негізінде зерттелетін материалдың дәл қалыңдығын анықтайды

Ультрадыбыстық қалыңдықты өлшеу металл конструкцияларды техникалық диагностикалаудың ең сенімді әдістерінің бірі деп есептеледі. Нәтижелерді алудағы қателік шамалы болып келеді. Бұл объектінің техникалық жай-күйін жылдам және дәл бағалауға және төтенше жағдайлардың пайда болуына жол бермеудің тәжірибелік тәсілі. Бақылаудың бұл тәсілі ұтымды болып табылады, себебі ол басқарылатын объектілерге зиян келтірмейді.

Қалыңдықты өлшеу үшін әуелі металда магнит өрісін жасау керек. Бұл үшін құрылғылар импульстік электр магниттерімен жабдықталған. Өлшеуді жүргізгенде, осы өріс арқылы ультрадыбыстық толқын металл қабырғасының бүкіл қалыңдығы арқылы өтіп, кері оралады.

Кері келген сигнал екі әдістің біреуімен өңделеді:

- тиісті төменгі сигналдар арасындағы уақыт интервалына негізделген әдіс бойынша;

- кез-келген төменгі және зондтаушы импульс арасындағы уақыт аралығына негізделген әдіс бойынша.

Ультрадыбыстық қалыңдықты өлшеудің негізгі артықшылықтары

- Қателіктерді болдырмау.

- Жұқа қабырғалы металл бұйымдарының қалыңдығын анықтау мүмкіндігі.

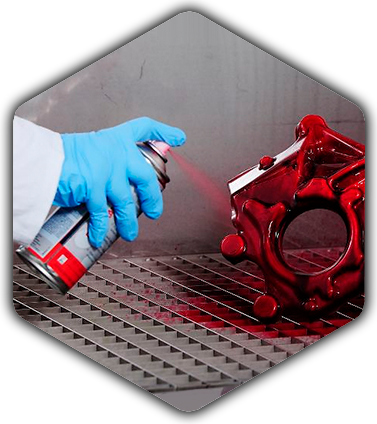

- Коррозия, бояу, лак және басқа оқшаулағыш жабындардан зардап шеккен қабаттың қалыңдығы туралы толық ақпарат алу

- Құрал-жабдықтың салыстырмалы төмен құны.

- Жазатайым оқиғаларды, бұзылуларды және қымбат жөндеуді болдырмау бойынша уақытылы шараларды қамтамасыз ету.

«ARDCON (АРДКОН)» ЖШС дәнекерлеу және металл бақылау зертханасының қызметтерін ұсынады. Зертхана мынадай тексеру әдістеріне ие: радиографиялық тексеру, ультрадыбыстық сынау, ультрадыбыстық қалыңдықты өлшеу, металл қаттылығын өлшеу, енгізілетін заттармен бақылау, магнитті ұнтақты дефектоскопия және басқа да бұзбай бақылау әдістері. Кеңес алу үшін әлеуетті тапсырыс беруші біздің техникалық мамандарымызға хабарласа алады және қызығушылық тудыратын мәселелерді талқылай алады.

Тел. +7 (7212) 996606,

Тел. +7 (708) 4360630

M02F3P7, Қазақстан Республикасы

Қарағанды облысы, ҚАРАҒАНДЫ Қ.

Штурманская К. 7, корпус 2

E-Mail: info@ardcon.kz