Magnetic particle inspection

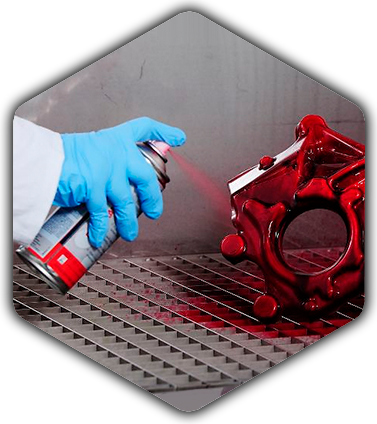

Magnetic particle method is used for testing products, parts, and welded joints of ferromagnetic material constructions with relative magnetic permeability of no less than forty, for the purpose of detection of surface and subsurface discontinuities invisible to the naked eye, such as flaws and incomplete penetration.

Magnetic particle method is based on recording stray magnetic fields arising above part defects on its magnetizing, with ferromagnetic particles (magnetic powder) that are suspended in dispersive medium or air. A magnetic particle in inhomogeneous magnetic field of a defect is effected by the force that attempts to draw it into areas of the highest concentration of force lines and to push it closer to the defect location. Presence and length of indication patterns found out by defect stray fields can be recorded visually or by automatic image processing devices.

Magnetic particle method serves to detection of surface and subsurface discontinuities, such as but not limited to hair cracks, flaws of different nature, incomplete fusions, flakes, laps, and tears.

Magnetic particle method is applied in nearly all industries:

- aircraft industry

- machine manufacturing

- automobile industry

- metals industry

- transport (aircraft, railway, automobile transport)

- ship building

- building (steelworks, pipelines).

LLP “ARDCON” offers services of welding and metal testing laboratory. The laboratory is certified to the following control methods: radiographic testing, ultrasonic flaw detection, ultrasonic thickness measurement, metal hardness measurement, liquid penetrant testing, magnetic particle inspection and other NDT methods. For consultation, a potential customer can contact with our technical specialists and discuss the questions.

Tel. +7 (7212) 996606,

Tel. +7 (708) 4360630

M02F3P7, Republic of Kazakhstan,

Karaganda region, Karaganda,

st.Navigational 7, housing 2

E-Mail: info@ardcon.kz