Hardness measurement

What is a reason of the hardness measurement?

One of the main characteristics which allow to evaluate the actual condition of the metals and alloys is their hardness. This testing method is one of the most widespread technical diagnostics methods.

Hardness testing is aimed at inspection of the metal usability for planned loads in certain exploitation conditions. Hardness means a metal’s ability to resist to mechanical penetration of other solid bodies in the surface. In other words, it is a metal strength to local plastic deformations caused by the impact of a harder object. The strength characteristics of the metal structures are directly depended on this factor.

What is an indenter?

Indenter is a steel ball, blower, cutting point and pyramid made from diamond. It is pressed into the surface of the testing material with a certain force. The hardness is evaluated according to the final dint character. This dint has an appropriate index number of the Vickers scale (HV), Rockwell (HRC) or Brinell (HB).

What methods of hardness measurement exist?

- Indenter impression (to evaluate the resistance to plastic deformations).

- Shock indenter impact or reverse rebound registration (to determine the elasticity).

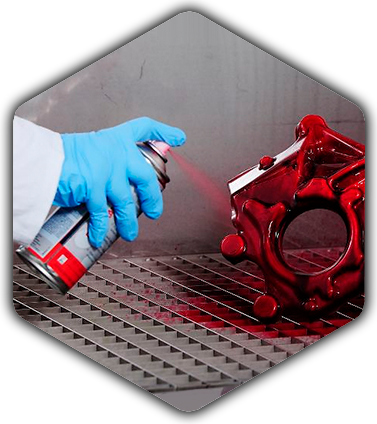

- Scratching (to evaluate the damage resistance).

- Continuous impression (displacement diagram and simultaneous exerting efforts recording).

The indenter load can be dynamic (impact force) or static (continuous pressing).

LLP «ARDCON» offers services of welding and metal testing laboratory. The laboratory is certified to the following control methods: radiographic testing, ultrasonic flaw detection, ultrasonic thickness measurement, metal hardness measurement, liquid penetrant testing, magnetic particle inspection and other NDT methods. For consultation, a potential customer can contact with our technical specialists and discuss the questions.

Tel. +7 (7212) 996606,

Tel. +7 (708) 4360630

M02F3P7, Republic of Kazakhstan,

Karaganda region, Karaganda,

st.Navigational 7, housing 2

E-Mail: info@ardcon.kz