Radiographic testing

The technical capabilities of the radiographic testing

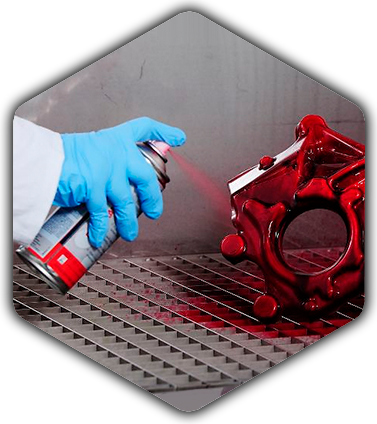

Radiographic testing is one of the most informative and reliable DNT methods. This method is overall used for diagnostic such facilities as pipelines of various diameters, metal constructions, technological equipment, products made from composites and so on. Technical equipment of “ARDCON” company includes X-ray machines RAYCRAFT; they are portable, safe and resistant to heavy field conditions.

Description and functions of the method

Radiographic testing is based on the use of X-ray penetrating power. Penetrating through the material, it has an impact on the photosensitive layer of the film, which is fixed on the back side of the welded joint. Rays are absorbed worse and increasingly affect the sensitive layer of the film in defective areas. At the end of testing, film is displayed. Decoding is performed using negatoscope (x-ray view box). Identified defects are clearly visible on the finished image, which makes it possible to register them and describe in details.

Radiographic testing can detect a variety of defects, such as:

- poor penetration

- pores

- tungsten, slag, oxide and other alien inclusions

- undercuts

- holes

- cracks

According to the prints, it is possible to estimate the convexity and concavity of the root; it is very practical, especially having limited access to it. X-ray film is selected in accordance with the technical requirements. In official regulations governing the control and inspection of welded joints, there are such parameters as:

- distance between the radiation source and the testing product;

- X-ray tube voltage;

- the use of metallic or fluorescent screens;

- dependence on the thickness of the material;

Advantages of radiographic testing

1. Detecting defects which are inaccessible to other NDT technologies (poor penetration, holes, etc.).

2. The exact localization of defects. Due to this advantage, the speed of the repair work increases significantly.

3. High reliability of testing, visual determination of the defects types and the amount of convexity and concavity of the stringer beads.

4. Archiving prints for re-analysis.

5. Automated interpretation of X-rays. It concerns modern hardware and software concepts, which are presented in our catalog.

6. Wide range of the use. This method is suitable for technical diagnostics of various facilities, such as pipelines, reservoirs, tanks, metal constructions, etc.

LLP «ARDCON» offers services of welding and metal testing laboratory. The laboratory is certified to the following control methods: radiographic testing, ultrasonic flaw detection, ultrasonic thickness measurement, metal hardness measurement, liquid penetrant testing, magnetic particle inspection and other NDT methods. For consultation, a potential customer can contact with our technical specialists and discuss the questions.

Tel. +7 (7212) 996606,

Tel. +7 (708) 4360630

M02F3P7, Republic of Kazakhstan,

Karaganda region, Karaganda,

st.Navigational 7, housing 2

E-Mail: info@ardcon.kz