Ultrasonic flaw detection

What is an ultrasonic flaw detection? Why is it popular?

Ultrasonic flaw detection is one of the NDT key methods. It allows to evaluate the reliability of welded structures.

Advantages and reasons of ultrasonic testing

This method is aimed at control of the welding quality, which influences directly on the work resource of pipelines, pillars, equipment, etc. Non-destructive testing is performed to prevent implementation of constructions having intolerable flaws in welded joints. In Western Europe and North America, the cost of technical diagnostics reaches 10-12% of the total project cost. It is better, cheaper and easier to detect the weak elements than pay for expensive repair process or liquidate the consequences of emergency situations.

This testing technology has a lot of advantages:

- cautious impact on the testing material without its damage

- precise and reliable data about actual object condition

- high rate diagnostics

- low testing cost

- portable equipment, possibility of diagnostics in the field

- absolute safety for the staff

Physical and mechanical testing basis

The ultrasonic flaw detection is a group of methods. These methods are similar in penetration using of elastic waves of ultrasonic testing frequency band. The key point of the method is that the trajectory of sonic waves does not change in a homogeneous material. If they come across any obstacles (for example, foreign bodies, or layering) characterized by different acoustic resistance, the waves are reflected from interface. Special devices which register these reflections are flaw detections.

Ultrasonic testing is performed to detect defects, including very small, as well as to determine their origin. Based on this information, the appropriate method is chosen to eliminate them.

What is the equipment for ultrasonic testing?

Modern flaw detections are popular and effective because of their powerful functionality. They can be set to a certain frequency to detect a wide range of defects. In most devices, it is possible to use several methods of ultrasonic testing, such as:

- shadow method

- delta method

- mirror-shadow method

- echo method

- mirror method

The combination of different measurement technologies makes testing more accurate and reliable. The operator receives the maximum amount of information for the assessment of defects and details compliance with regulatory requirements.

In recent years, flaw detectors working with the support of phased arrays are the most widespread. Their main advantage is that they allow to obtain 3D-images of defects in the material.

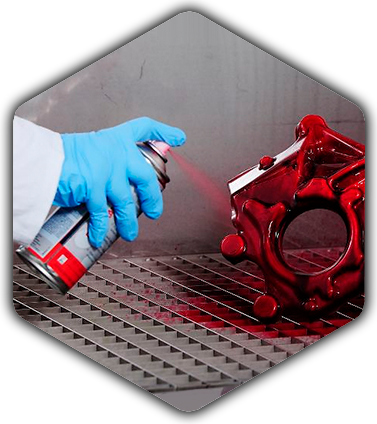

LLP «ARDCON» offers services of welding and metal testing laboratory. The laboratory is certified to the following control methods: radiographic testing, ultrasonic flaw detection, ultrasonic thickness measurement, metal hardness measurement, liquid penetrant testing, magnetic particle inspection and other NDT methods. For consultation, a potential customer can contact with our technical specialists and discuss the questions.

Tel. +7 (7212) 996606,

Tel. +7 (708) 4360630

M02F3P7, Republic of Kazakhstan,

Karaganda region, Karaganda,

st.Navigational 7, housing 2

E-Mail: info@ardcon.kz