Visual and measurement testing

What problems does visual and measurement testing solve?

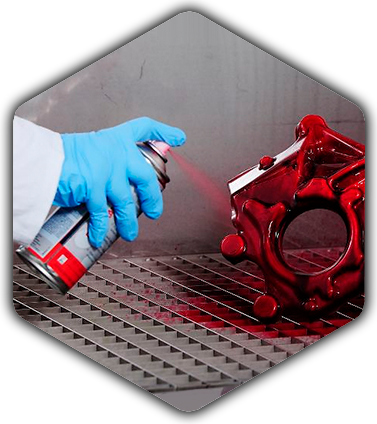

Visual and measurement testing is performed to obtain initial information about the object under inspection (VMT). VMT is directed at testing of blank parts quality for melding and also evaluation of welded joints quality. External expertise is an integral part of technical diagnostics. It is performed not depending on using other DNT methods.

The main advantages of this method:

- sufficient information content

- efficiency, frugal cost of equipment and consumables

- operational capability, quick receiving of information about the object

- lower requirements for staff qualification

Visual and measurement testing is effective for detection of discontinuity flaws and determination of deviations from assigned geometry. Depending on the tasks, diagnostic is performed by the naked eye or using of magnifying loupes (with 10- or 20-fold power) and special equipment.

Surface area is cleaned for testing process from such impurities as:

- dross

- rust

- dust

- oil

- metal splashes

- paint fragments

Testing zones of this method are welds and joining metals in width from 20 mm on both sides. As a rule, VMT is preceded to testing by other methods. Subsisted defects at this phase must be eliminated before testing by other methods.

Optical testing is performed using the following measurement instruments and tools:

- measuring magnifier

- caliper

- metal ruler

- inclinometer

- triangle

- stylus instrument

- sampler

Despite the simplicity, VMT is effective method to detect defects and prevent emergencies. This method allows to determine the deviation of the geometric characteristics from assigned parameters and also subsist cracks, nicks, layering, folds, holes, slag inclusions and other visual defects.

VMT using cases:

1. Inspection testing of materials.

2. Elements preparation for assemblage and welding. Components are checked to determine their compliance with the requirements for clean and edge preparation, estimate the gap setting, as well as the amount, reliability and tacks position. In addition, inspection is performed to verify the absence of surface and angular shifts.

3. The final phases of welding works and their ending. Weld defects check for the absence of such flaws as cracks, holes, pores, burn marks, overlaps, rough scales, poor penetration, low spot between beads and others. It is necessary to evaluate maintenance of the weld geometry according to regulatory requirements.

4. Subsequent technical diagnostics. During exploitation it is possible that the base metal and welded joints may be exposed to corrosive pits, fatigue cracks and other defects. They must be detected earlier to spend less time and required expenses for the repair process.

LLP «ARDCON» offers services of welding and metal testing laboratory. The laboratory is certified to the following control methods: radiographic testing, ultrasonic flaw detection, ultrasonic thickness measurement, metal hardness measurement, liquid penetrant testing, magnetic particle inspection and other NDT methods. For consultation, a potential customer can contact with our technical specialists and discuss the questions.

Tel. +7 (7212) 996606,

Tel. +7 (708) 4360630

M02F3P7, Republic of Kazakhstan,

Karaganda region, Karaganda,

st.Navigational 7, housing 2

E-Mail: info@ardcon.kz